Editor's note: This article is the latest in a series that looks into the ways supply chains, warehouses and manufacturing facilities are investing in technology. Here's the previous story.

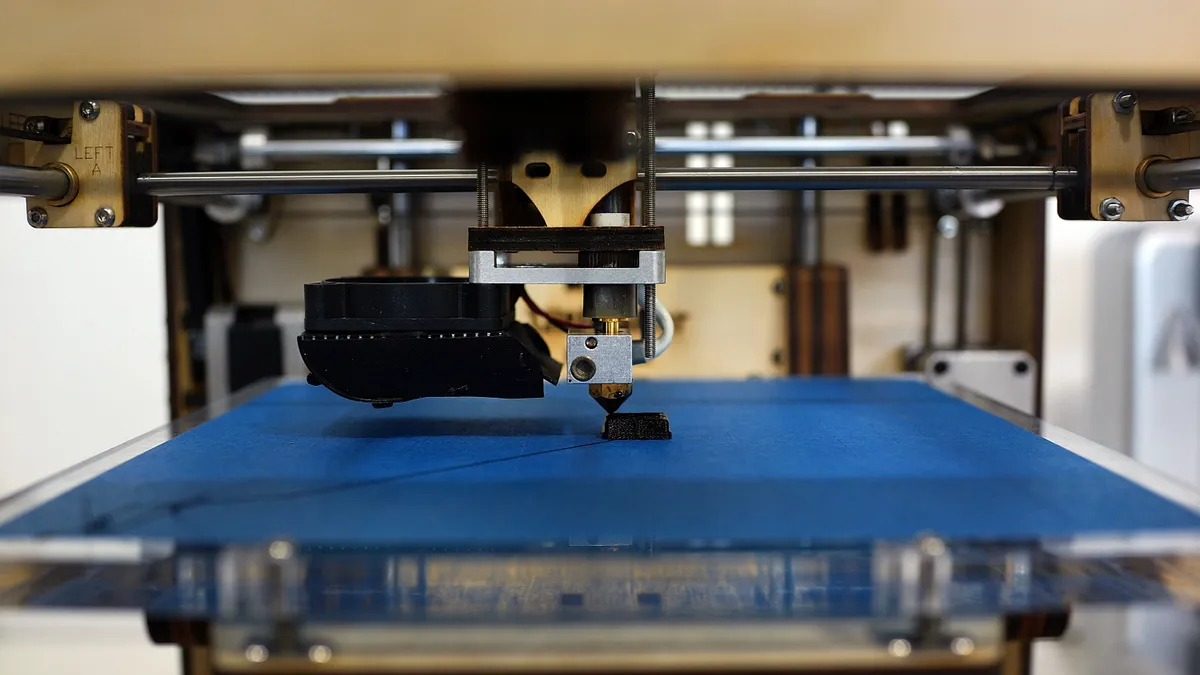

3D printing is changing the way manufacturers and supply chain professionals think about the way they make, with some using the technology to take production outside of the warehouse altogether.

An MHI and Deloitte survey last year of more than 1,000 supply chain professionals found 21% of companies currently use 3D printing and additive manufacturing, while 32% plan to invest in the technology in the next five years. The rising popularity of 3D printing is driving innovation and change in the way businesses use the technology within their supply chains.

With advances in machines and materials, "you start to see people getting a lot more creative about what’s actually getting printed, and where it’s being printed," said Scott Buchholz, emerging tech research director at Deloitte.

Better processes and materials propel 3D printing

The rapid adoption of additive manufacturing is being driven by improvements in just about every aspect of 3D printing. Machines are faster, more precise and can handle more volume. There are also more options as to what can be made, with ways to 3D print things like high temperature plastics and metals.

Manufacturers and supply chain specialists are increasingly looking at how the technology could apply to their work, according to John McEleney, corporate vice president of strategy at PTC and co-founder of product development platform Onshape.

"When you look at the supply chain, people are augmenting their supplier strategy," McEleney said. "It’s been quite profound."

Companies are investing millions of dollars in 3D printing

GE Aviation, for example, uses 3D printing to make nozzle tips for LEAP engines, which are commonly used in commercial aviation. The technology allows the tips to be created with just one piece, instead of the usual 20.

Advances in other technologies, like cloud computing, have also enabled wider adoption of 3D printing and additive manufacturing, McEleney added. Cloud-based web tools mean that designers and manufacturers can work on prototypes and better collaborate, "therefore changing the nature of what suppliers do."

Customization gets companies closer to consumers

3D printing is also expected to change the way retailers interact with consumers. Since the technology is so customizable, it's possible for businesses to quickly manufacture items in-store based on customer specifications.

"I would like to see that we get a lot more customer clothing manufactured for us at a local store as opposed to generically fit clothing constructed thousands of miles away," said Buchholz of Deloitte.

That’s already happening in the medical and dental fields, which is expected to be the largest end user of 3D printing by 2030 according to Lux Research. Aligner orthodontics such as Invisalign can now be 3D printed at the dentist's office instead of being manufactured off-site and mailed. Superfeet uses HP’s FitStation machines to scan feet to build custom orthotics that can be sent to customers in about a week, cutting down on time and cost of acquiring inserts.

Advances in 3D printing and additive manufacturing may also change how supply chains are designed in the future, Buchholz added. If more items become custom printed, the location of a 3D printer could redefine where a company needs its raw materials stored or the facility processing its end-products.

"Do you change the nature of your packaging?" said Buchholz. "Suddenly you start being able to ask all sorts of interesting questions around does it need to be in a box, does it need to be in a plastic bag?"

This story was first published in our Operations Weekly newsletter. Sign up here.