Manufacturing is making a comeback in the United States. From reshoring investments to advanced automation, this resurgence is reshaping how products are built and delivered. But behind every production line lies a critical, often overlooked factor in that transformation: the warehouse.

Once viewed as passive storage, warehouses are now becoming active, data-driven components of the manufacturing ecosystem. When they fail, the effects ripple across supply chains. According to McKinsey, disruptions cost manufacturers an average of 45% of one year’s profits over a decade. With tariffs, labor shortages, and shifting demand increasing the strain, the ability of warehouses to operate efficiently has become a defining competitive advantage.

Three emerging technologies - robotics, digital twins, and data intelligence - are driving this change and turning warehouses from cost centers into strategic assets.

Robotics: The Foundation for Agility and Scale

Robotics in the warehouse has evolved far beyond simple pallet movement. Today’s systems combine autonomous mobility with real-time sensing and AI to perform tasks once reliant on manual labor. Robots can manage picking, packing, and cycle counting, freeing up teams to focus on problem-solving rather than repetition.

For manufacturers, this shift means higher throughput, fewer production interruptions, and faster access to materials. Automation also provides flexibility. As demand fluctuates, robotic systems can scale capacity up or down without requiring major infrastructure changes. This is critical in a market defined by uncertainty.

Digital Twins: Real-Time Decision Support

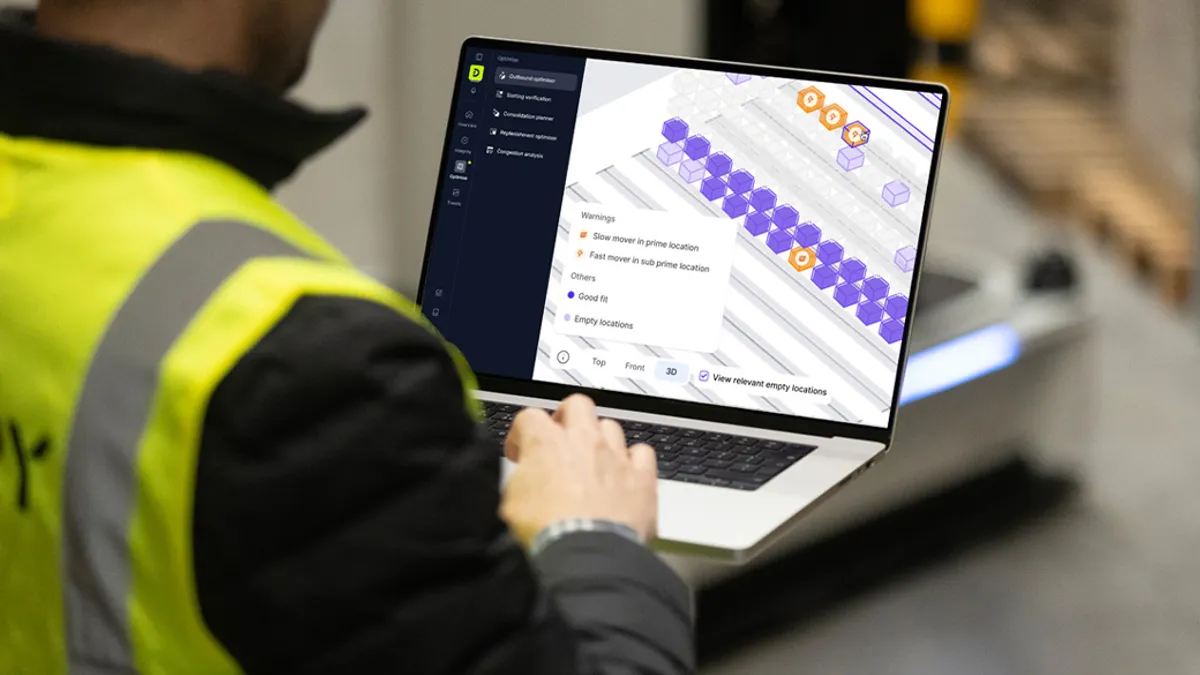

Digital twins, a virtual replica of the warehouse that mirrors operations as they happen, give manufacturers the ability to simulate changes, forecast capacity, and test layouts before investing in physical reconfiguration.

The results can be substantial. A Capgemini study found that organizations using digital twins achieved a 15% improvement in operational efficiency and more than a 25% increase in system effectiveness. Gartner predicts that by 2027, over 70% of enterprises will use digital twins to improve performance.

In manufacturing environments where every minute of downtime has a huge financial impact, this level of insight is invaluable. Digital twins help ensure materials and components are always in the right place at the right time and that supply interruptions can be anticipated before they happen.

Data Intelligence: Connecting the Dots Across Operations

Warehouses generate millions of data points daily, but only recently has technology advanced enough to make that data truly actionable. Modern data intelligence platforms now integrate robotics and digital twins, creating a unified view of stock, space, and performance across the network.

A recent Forrester Total Economic Impact report shows that intelligent warehouse systems can achieve 99.9% inventory accuracy, cut manual stock counting by 80%, and reduce stockholding time by 30%. These gains align directly with lean manufacturing goals, supporting continuous flow and minimizing waste.

When paired with predictive analytics, these systems allow manufacturers to shift from reacting to issues to preventing them, in turn protecting productivity and profitability.

Building the Intelligent Warehouse Ecosystem

Each of these technologies delivers strong results on its own, but the real power comes from their integration. Robotics deliver physical precision, digital twins provide operational context, and data intelligence connects them both to create a self-learning ecosystem.

As manufacturers expand or modernize, this ecosystem allows warehouses to adapt dynamically to demand surges, supply chain shocks, and resource constraints. The payoff is tangible: greater agility, higher accuracy, and a foundation for sustainable growth.

Warehouses as a Strategic Advantage

The conversation about U.S. manufacturing growth often centers on new facilities and automation on the production floor. Yet it is the warehouse - when equipped with intelligence, automation, and real-time data - that ensures those factories can run without interruption.

By investing in smarter warehouse technologies today, manufacturers can create supply chains that are not only more efficient but also more resilient and competitive. The next leap forward in U.S. manufacturing will not begin on the assembly line. It will begin in the warehouse.