Industry 4.0 is quickly becoming a reality, transforming not just production processes but also the way logistics managers operate.

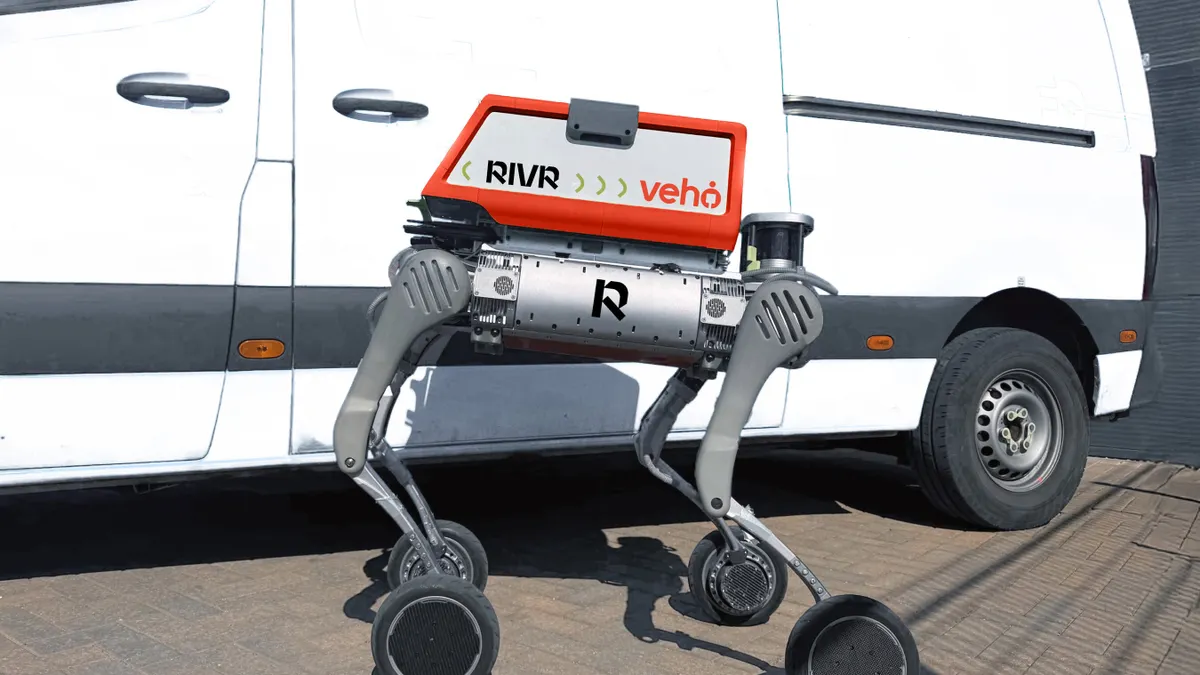

Experts say we’ve reached a tipping point in technology, with rapid adoption forcing changes across the supply chain. Data-driven strategies, involving robotics and the internet of things (IoT), are now commonplace.

A recent report by the Society of Manufacturing Engineers found while only 3% of surveyed companies are ready for large scale deployment of Industry 4.0, more than half are already experimenting with smart manufacturing technologies.

As these smart initiatives make manufacturers more flexible, it is changing the expectations of their partners: touching suppliers, distributors and even logistics companies on the consumer end.

Smart manufacturing strategies move beyond factory walls

As the supply chain moves from a linear path to a dynamic network, many manufacturers view supply chain as a critical component of Industry 4.0, Pete Guarraia, partner and leader of the global supply chain practice at Bain & Company, told Supply Chain Dive. Manufacturers consider partners on the supply and distribution end not only in terms of performance but in competitive advantages they can help achieve.

"They organize for success and then they look at logistics," Guarraia said. "They look at how they can use technology to close performance gaps in the supply chain."

Some manufacturers are seeking customization as their competitive advantage while others are aiming for speed. The "Amazon effect" is creating ripple effects throughout the entire industry and setting new expectations for the future of supply chain managers, Guarraia said.

In many parts of the retail and B2C space, consumers can now order custom-made products with their smartphone then track progress from raw materials to work in progress to finished goods and in delivery. "We know you’re not going to order a skid-steer loader on your smart phone but there’s a whole generation of supply chain executives that are being raised with the Amazon expectations at the top of their mind, and they want infinite flexibility," Guarraia said.

Many manufacturers are also looking to 3D printing to enable more last-minute and customized production, Vivek Soneja, Global Head SCM Line of Business at Anaplan, told Supply Chain Dive.

HP is already using its own 3D printing technology to build its own parts, and Boeing is set to use 3D-printed titanium components on its new 787 Dreamliner planes. Some smaller manufacturers are moving to production solely through 3D printing while others are using it in packaging to offer last-minute flexibility.

"[3D printing] gives the supply chain and logistics commercial model flexibility ... It completely changes how you think about the logistical distribution of a product," Soneja said.

In the customer-driven era of customization and rapid fulfillment, reverse logistics are becoming increasingly important for manufacturers. Many are moving to a product-as-a-service model that has the original equipment manufacturer (OEM) taking more responsibilities for maintenance, upgrades and keeping the platform operational.

"There are distinct ways of getting the products back into the service shop and associated reverse logistics with it, and then processes around receiving," Soneja said. "The logistics associated with it are completely different."

Competitive advantages for logistics companies that can adapt

While many of these technologies have been on the market for years, we have reached a point where the value of application is "finally coming to fruition," Guarraia said.

A report by the Smart Manufacturing Experience found 43%of manufacturers say the industry is already seeing significant changes due to digital technology solutions. Smart manufacturing can offer increased productivity, improved operations, better decision making and increased competitiveness, it noted.

Manufacturers typically must start with a roadmap and framework that includes the integration of business and manufacturing systems. And as the goals often revolved around speed, quality and providing more value to customers, that roadmap often starts with suppliers and logistics providers.

Despite the shift towards visibility and recent trends, there’s still a "bit of misalignment" between the manufacturers and many logistics providers, said Rob Stevens, co-founder and CRO at Tive. "The manufacturers want to know what’s really going on, and to some extent, that’s not always in the interest of the carrier and (logistics service provider)," he said.

Leading players in the freight forwarding and third-party logistics space have "flipped over and are now talking about how they can respond to this in a positive way," said Stevens. They typically want to say yes to the customer that wants to know where their stuff is, and they are looking to tools and technologies that can provide visibility.

Certainly, there are companies that will not be able to make this jump in technology and meet the needs, Guarraia said.

Digitization is already affecting significant changes in the supply chain of the auto industry as vehicle manufacturers demand new and more innovative components. These suppliers are "scrambling and will do quite well from the jump to smart manufacturing," Guarraia said.