PepsiCo is testing AI and digital twin technologies to assess their effectiveness in simulating, validating and optimizing plant and warehouse facilities before making any physical changes.

The branded consumer packaged goods company has started an early-stage pilot of the technology with AI chipmaker Nvidia and global industrial technology company Siemens, according to a Jan. 6 press release. The companies aim to remake PepsiCo's plant and supply chain operations through a multi-year collaboration.

"The scale and complexity of PepsiCo’s business, from farm to shelf, is massive—and we are embedding AI throughout our operations to better meet the increasing demands of our consumers and customers,” PepsiCo Chairman and CEO Ramon Laguarta said in the release.

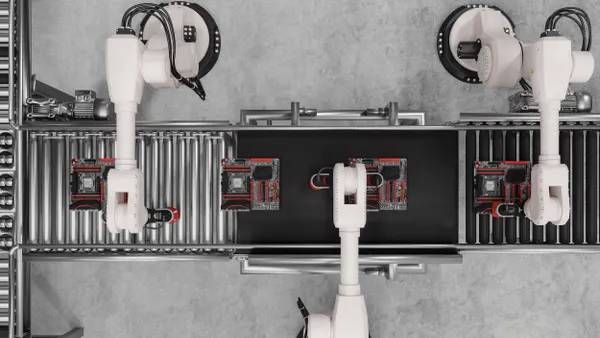

As part of its digital-first planning strategy, PepsiCo is using digital twins and AI agents as co-designers of facility layouts, specifically utilizing Siemens Digital Twin Composer, built on Nvidia's Omniverse AI toolkits.

A digital twin is a real-time virtual model of a physical asset, system or process. Companies, such as Amazon and Walmart, use this technology to simulate the effects of operational changes or additions. PepsiCo plans to first simulate upgrades to its U.S. facilities, then expand globally, starting with its biggest markets this year and 2027, the company said in an email to Supply Chain Dive.

“Working with NVIDIA and Siemens, PepsiCo is re-architecting its operations—using physically accurate digital twins and AI to reinvent how it designs, optimizes, and runs its global operations," Nvidia founder and CEO Jensen Huang said in the release.

PepsiCo and Siemens have converted selected U.S. manufacturing and warehouse facilities into high-fidelity 3D digital replicas, per the release. The conversion helps establish a performance baseline for plant operations and the end-to-end supply chain. Teams use the virtual twin to validate and optimize new configurations meant to boost capacity and factory line throughput.

The Siemens technology enables PepsiCo to recreate every machine, conveyor, pallet route and operator path with physics-level accuracy, according to the release. The snacks manufacturer can use AI agents to simulate, test and refine system changes, helping it identify up to 90% of potential issues before making any physical changes, per the companies.

"With a unified, AI-powered digital foundation, PepsiCo is building toward a world where every plant and warehouse operates as part of a single, intelligent ecosystem," Athina Kanioura, CEO of Latin America and global chief strategy and transformation officer at PepsiCo, said in the release. "In this future, our facilities don’t just respond to demand, they anticipate and then adapt to it."

This story was first published in our Operations Weekly newsletter. Sign up here.