Editor’s note: This story is part of a series highlighting takeaways from a July 23 event hosted by Supply Chain Dive, Trucking Dive, Manufacturing Dive and Packaging Dive. Register here to watch the replay on demand.

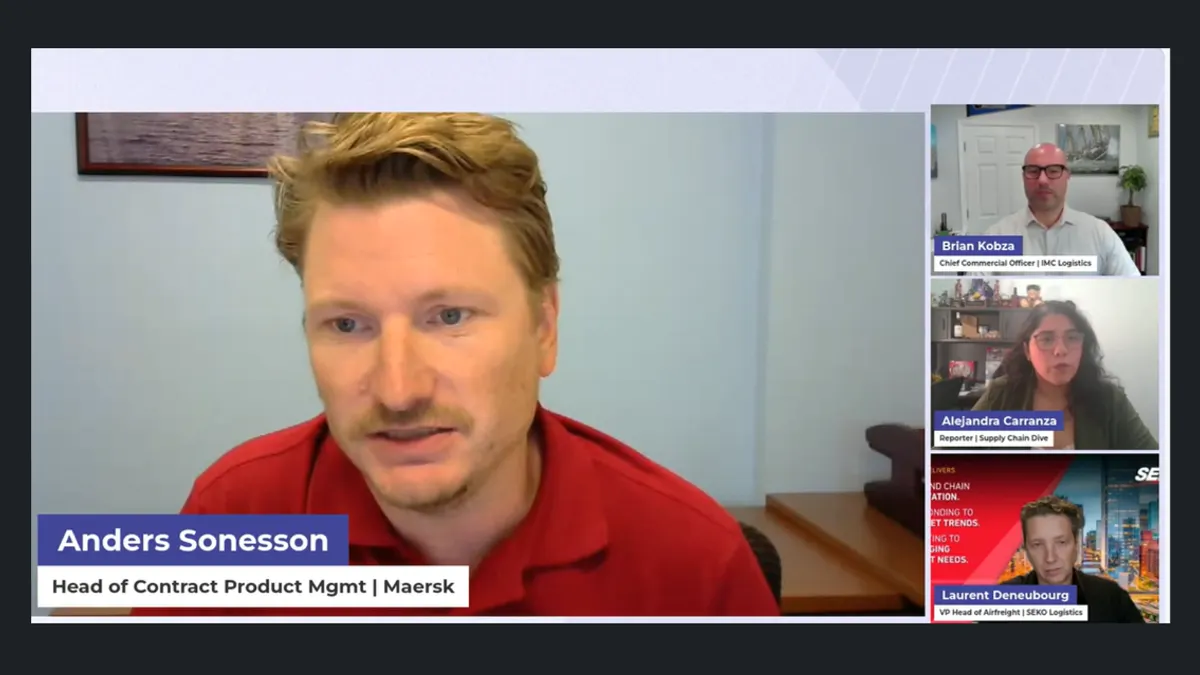

Maersk is prioritizing cost avoidance to mitigate impending fees on China-linked vessels, said company executive Anders Sonesson during Supply Chain Dive’s July 23 event, “Supply Chain Outlook: Trends and Risks to Watch in 2025.”

Sonesson, who serves as head of contract product management for North America at A.P. Moller - Maersk, also mentioned that the ocean carrier can easily deploy China-built ships on other tradelanes due to its global network, which will remain unchanged.

“We’re also not going to put any Chinese-built ships into the U.S. trade if that’s going to cost millions of dollars to call U.S. ports,” Sonesson said. “So, I think that's also what I'm expecting to see from the rest of our competitors and the alliances.”

In April, the Office of the U.S. Trade Representative introduced a free structure targeting China-linked vessels. Starting Oct. 14, China-linked ships calling at U.S. ports will face fees ranging between $18 per net ton to $120 per container. Those rates will then rise every subsequent April.

The fees are intended to bolster domestic shipbuilding, according to the USTR. However, some stakeholders are skeptical of the impact, saying it would heighten shipping costs and consumer prices without actually boosting the U.S.’ role in ocean shipping.

Maersk doesn’t intend to charge customers any fees or surcharges related to the proposal, as it is not realistic to force shippers to cover costs they have no control over, according to Sonesson.

“It will be very difficult for us to justify to our customers why you should pay because you load it on a Chinese-built ship because it's not really up to the customers to choose what vessel they load on,” he said.

IMC Logistics Chief Commercial Officer Brian Kobza said the proposal would likely push ships to consolidate ports, leading to congestion.

“Anytime you see more volume spiking into [a] single port, that type of congestion has a lot of downstream effects, into the [distribution centers], into the trucking community, into the delays and the turn times of trucks and rails in the ports,” said Kobza. “Any time you create that type of congestion, you're just adding cost and reducing reliability in the supply chain.”