Dive Brief:

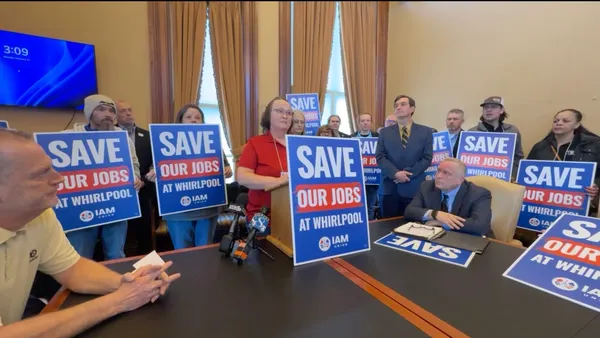

- La-Z-Boy raised prices following the Trump administration's imposition of Section 232 tariffs on upholstered furniture, according to a Nov. 19 earnings call.

- However, the manufacturer's price increases throughout 2025 were in the single digits, which was at "the very low end of what we're hearing is out in the market," SVP and CFO Taylor Luebke told investors.

- "In our quarter, on our main North America wholesale La-Z-Boy business, we saw volume flat year-over-year, which relatively speaks to our pricing is going well in the market," Luebke said.

Dive Insight:

La-Z-Boy has remained confident that it was better positioned to mitigate tariffs than its competitors because it makes nearly all of its products in the U.S., Luebke said. Also, the company had adjusted its production to align with the government's trade policies.

Therefore, the company did not expect to raise prices again if the Trump administration goes through with its plan to increase tariffs on upholstered furniture to 30% on Jan. 1, 2026. The company previously raised prices due to the trade policy developing in 2025, executives noted in June.

"Obviously, we'll continue to be agile if anything changes between now and then, but overall, we feel really good and well-positioned with 90% of our product made in the U.S.," Luebke said.

Besides discussing tariffs, La-Z-Boy executives provided an update on the multiyear redesign of the company's distribution network for a leaner, more effective supply chain that can deliver consistent double-digit operating margins. The goal of the project, started in the spring, is to reduce the company's distribution footprint from 15 large distribution centers to three centralized hubs, the first of which opened this year.

In the second quarter, which ended Oct. 25, La-Z-Boy consolidated an additional two distribution centers, President and CEO Melinda Whittington said. Ultimately, the company expected an estimated 30% reduction in square footage across its warehouse network, a roughly 20% drop in mileage for inventory traveling across the network, and a doubling of the delivery radius from 75 to 150 miles.

However, the supply chain modifications had their costs, which Luebke called "manageable."

"You just have to get a little bit more inefficient in the short term to get way more efficient ongoing," the CFO said.