Dive Brief:

- Conagra Brands plans to increase investments to support supply chain resiliency as part of the roughly $450 million it earmarked for capital expenditures in fiscal year 2026, per a July 10 earnings call presentation.

- The food maker faced several supply challenges in FY25, which ended May 25, including stalled chicken production, a frozen vegetable shortage and tariffs on tinplate steel used to make canned food containers.

- “We expect these incremental investments to more than offset the favorable lapping impact of fiscal '25 supply challenges,” CFO David Marberger said on a July 10 earnings call. Conagra did not respond to an email from Supply Chain Dive on how much of its planned capex would go toward its supply chain specifically.

Dive Insight:

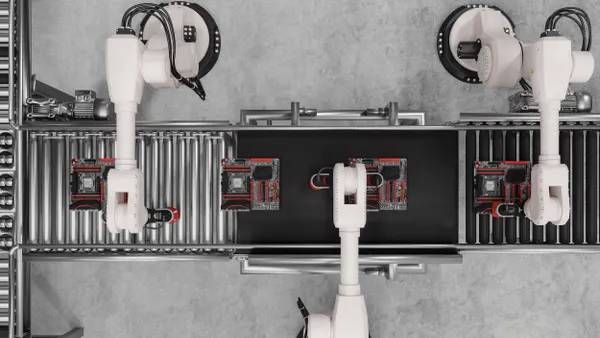

Conagra’s plans to increase investments for its supply chain come as it reconfigures its production capabilities.

The food maker aims to significantly boost chicken production over the next 12 months to meet higher-than-expected demand for new products and reduce the cost of using third-party manufacturers, executives said on the earnings call.

Conagra’s upgrade efforts became urgent in Q3 of FY25 when the company discovered “product quality inconsistencies” on the production lines of its primary facility for preparing and cooking chicken used in frozen meals, per a February statement.

The discovery forced Conagra to temporarily stop production, make operational adjustments and turn to third-party manufacturers to maintain sufficient production levels while upgrading the faulty facility.

Also in FY25, demand for Conagra’s new Banquet Mega Chicken Filets “absolutely blew away our expectations,” leading to plans to increase chicken capacity, CEO Sean Connolly told analysts.

“And so we now have decided to double down on our investment in fried chicken capacity,” Connolly said. “It’s going to be more costly next -- this year because we’re going to do it on the outside, but then we’ll repatriate that on the inside.”

Conagra has taken steps to modernize its chicken production facilities to fix constraints in baked chicken that it encountered in FY25. The company expects to complete the project by early Q2 of the current fiscal year, Connolly said in pre-recorded remarks ahead of the July earnings call.

The company has also resolved supply challenges in its frozen vegetable business, according to Connolly. In FY25, Conagra invested in increasing surge capacity after consumption growth rates nearly doubled through December and into early January 2025. The spike depleted on-hand inventory, which led to out-of-stocks in stores, the company said in the February statement.

Conagra’s production changes have also included a facility closure. In April, the company notified Michigan’s labor department that it would shutter its pie-filling plant in Fennville, Michigan, by the end of June and lay off 75 workers "to improve efficiencies and effectiveness within its supply chain network."

Conagra expects to capitalize on its supply chain investments in fiscal 2027, Connolly said. Until then, margins will take a hit due to inflation and the additional production costs.

“Unfortunately, inflation across fiscal ’25 and fiscal ’26 combined adds about another 11% of cost, and the confluence of high inflation and higher investments to drive volume translates to temporary margin compression,” Connolly said.